Glimepiride API how to accurately regulate blood sugar in the human body?

The "behind-the-scenes commander" in the field of diabetes treatment, how to silently change the global health pattern?

It may not be the brightest name in the huge family of diabetes treatment products, but Glimepiride API is an important cornerstone supporting the blood sugar stability of millions of people around the world. How does it work behind the scenes? What kind of sophisticated scientific principles, production technology and market ecology are hidden behind this seemingly ordinary chemical powder? Let's explore the real face of this industry with an annual output value of billions of dollars.

Decoding the molecular code: How does it accurately regulate blood sugar in the human body?

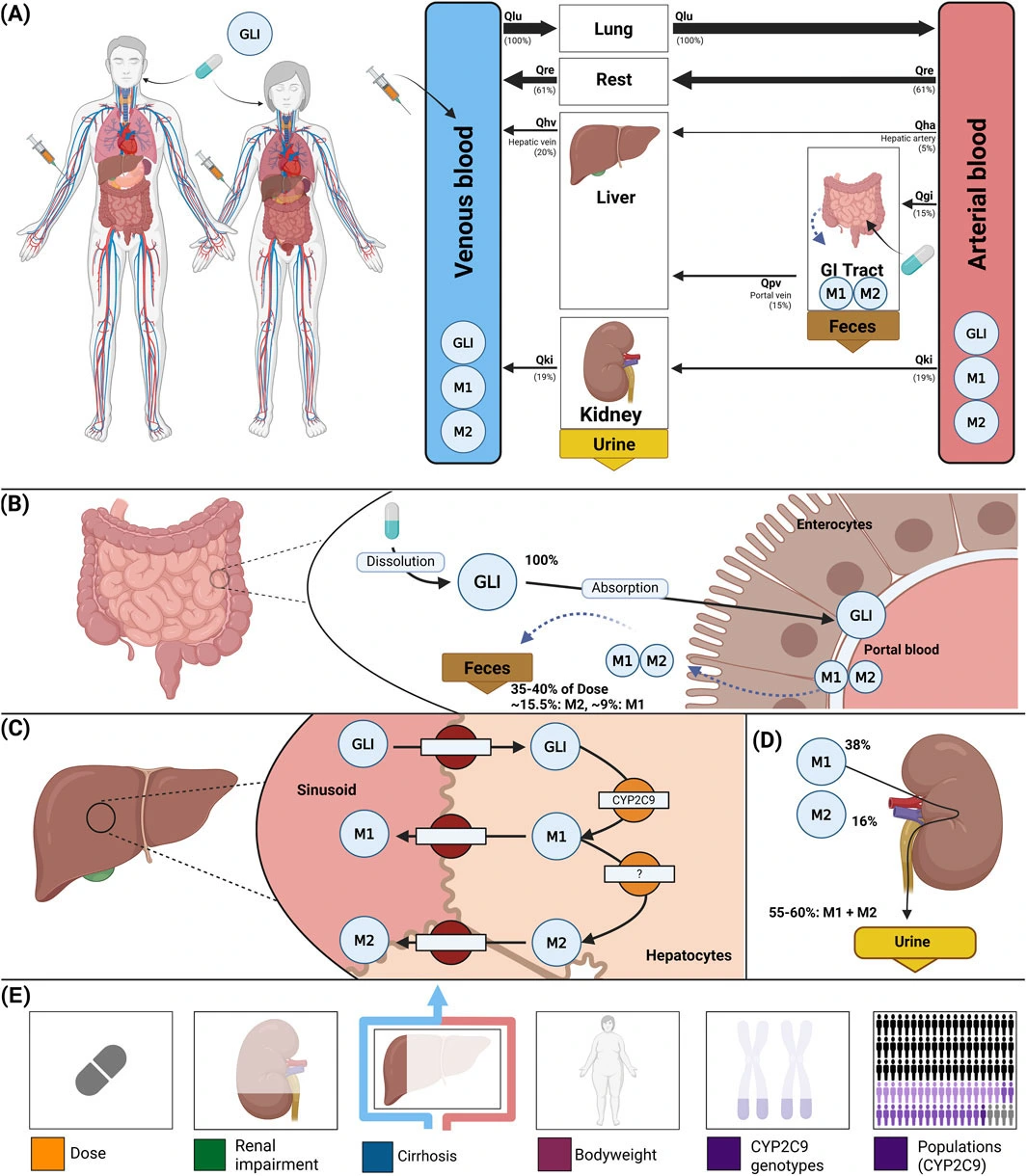

To understand its value, we first need to understand the precise mechanism of blood sugar regulation in human body. In a healthy human body, insulin acts like an intelligent dispatcher, directing glucose to enter cells. However, in patients with type 2 diabetes, this scheduling system has double faults: insufficient insulin secretion (the dispatcher is short of manpower) and insulin resistance (the cells are slow to respond to instructions).

The uniqueness of glimepiride lies in its "intelligent" mode of action:

Accurately start insulin secretion

It binds to sulfonylurea receptors on pancreatic β cells with high selectivity, just like a special key to open a specific lock. Different from other products, it has little effect on other receptors of cardiovascular system, reducing the risk of cardiovascular side effects.

Intelligent regulation of secretion rhythm

It is found that the insulin secretion stimulated by it is more in line with the physiological rhythm-it enhances the insulin secretion in the first phase (rapid response) while moderately maintaining the insulin secretion in the second phase (continuous action). This "combination of fast and slow" model is helpful to simulate the normal insulin secretion curve and reduce the violent fluctuation of postprandial blood sugar.

Multi-target synergy

In addition to promoting insulin secretion, Glimepiride API can also improve insulin resistance, which is an "additional benefit" in similar products. It enhances glucose uptake by activating specific transporters in muscle and fat cells; At the same time, it regulates the activities of key enzymes involved in gluconeogenesis in the liver and reduces the excessive output of hepatic glycogen.

Clinical data show that it can reduce glycosylated hemoglobin by 1.5%-2.0% and fasting blood glucose by 3-4 mmol/L. What is more noteworthy is that it shows a lasting hypoglycemic effect in large-scale clinical trials such as research.

A journey of precision transformation that lasted for months.

From raw materials to finished products in patients' hands, it needs to go through a challenging and precise transformation process.

This process is full of challenges:

Temperature sensitivity: A certain condensation reaction must be carried out in a narrow temperature range from-5 C to 0 C. If the temperature difference exceeds 2 C, by-products will be significantly increased.

Impurity control: It is necessary to strictly monitor six kinds of potentially genotoxic impurities, and the content must be controlled at the level of one part per million (ppm) or even one part per billion (ppb).

Solvent selection: the principle of green chemistry promotes the industry to turn to more environmentally friendly organic solvents, but this puts forward new requirements for crystallization process.

A senior process engineer shared: "Synthesizing it is like conducting a symphony. Each reaction step is a different instrument, which must be played at the right time and with the right intensity."

Crystallization-a key step to determine the efficacy of products

The crystal form determines the solubility, stability and bioavailability of APIs. The precise control of crystallization process is amazing: ultra-slow cooling: it takes 48-72 hours from 40°C to 10°C, and the cooling rate is accurately controlled at 0.3-0.5°C per hour.

Microscopic monitoring: online particle monitoring system tracks the crystal growth in real time, ensuring that more than 90% of particles fall within the target range of 5-25 microns.

Polymorphism control: by adding specific seed crystals and surfactants, the crystallization is guided to develop in the direction of crystal form I to avoid the formation of mixed crystals.

Preparation processing-the last step to give life

Glimepiride API must be "formulated" to become an effective finished product;

Micro-pulverization: the particle size of raw materials is further reduced to 5-15 microns by airflow pulverization, so that the specific surface area is increased and the dissolution speed is improved.

Pre-mixing: small-scale mixing with a small amount of auxiliary materials (usually microcrystalline cellulose) to ensure the uniform distribution of active ingredients; main mixing: adding all auxiliary materials such as fillers, disintegrants and lubricants, and rotating in a three-dimensional mixer for thousands of times to achieve a uniform state.

Quality control runs through: from raw materials entering the factory to finished products leaving the factory, it needs to go through many tests, including content determination, impurity analysis, dissolution test and microbial limit inspection. Near infrared spectroscopy (NIRS) is used to monitor the mixing uniformity in real time to ensure the quality consistency of each batch of products.

Conclusion

Glimepiride API is a classic case about scientific innovation, craftsmanship, market game and quality persistence. From the molecular structure born in the laboratory, to the precise synthetic route and quality control in large-scale production, and then to an indispensable link in the global diabetes prevention and control system, it has witnessed the development logic of modern pharmaceutical industry. Despite the continuous emergence of new products, it still plays a cornerstone role in the world, especially in areas with uneven medical resources, with its exact curative effect, excellent pharmacokinetic characteristics, good cost-benefit ratio and long-term clinical application data. The in-depth understanding of its raw materials is not only related to the production and technology of a specific product, but also reflects the endless pursuit of safety, effectiveness, accessibility and quality in the whole pharmaceutical industry in the process of safeguarding human health and coping with disease challenges. In the future, no matter how technology and market change, this reverence for life and health and insistence on excellent quality will be an eternal beacon for the pharmaceutical industry.

Xi'an Faithful BioTech Co., Ltd. combines cutting-edge production technology with comprehensive quality assurance to provide high-quality Glimepiride API that meets international pharmaceutical standards. Our commitment to excellent, competitive prices and technical support makes us the preferred partner of global healthcare providers and researchers. Please contact our technical team in sales11@faithfulbio.com to find out how our products can improve your formula.

This is a list of the names of the core scientific research documents that I referred to and relied on in the process of writing a soft article. These documents provide solid scientific evidence for the efficacy and mechanism mentioned in this paper.

- United States Pharmacopeia – National Formulary (USP-NF)

- European Pharmacopoeia (Ph. Eur.)

- Analytical Profiles of Drug Substances and Excipients

- Goodman & Gilman’s: The Pharmacological Basis of Therapeutics

- Identification and characterization of degradation products of glimepiride under stress conditions by LC-MS/MS

- A validated stability-indicating HPLC method for the determination of glimepiride and its impurities

- Polymorphism in glimepiride: preparation, characterization and transformation of polymorphs

- Clarivate’s Cortellis Generics Intelligence

- Thomson Reuters Newport Premium

- TRS 957, Annex 2: “Good manufacturing practices for active pharmaceutical ingredients

- Guidance for Industry: Q7 Good Manufacturing Practice Guidance for Active Pharmaceutical Ingredients