How to Compound Gabapentin Powder: A Step-by-Step Guide for Pharmaceutical Use

To make sure that the medicine works and that it follows the rules, gabapentin powder mixing needs to be done in a very specific way and with strict quality controls. This pharmaceutical precursor is an important part of brain medicines, so it needs to be handled in a certain way and produced according to GMP standards. In clinical settings, bioavailability, stability, and patient safety are all directly affected by the right combination of procedures.

Understanding Gabapentin Powder and Its Pharmaceutical Applications

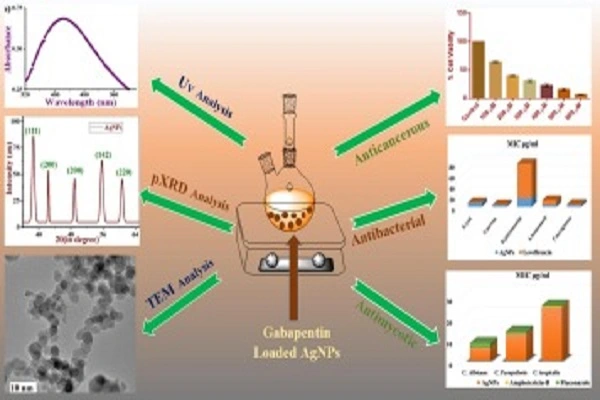

Gabapentin powder is a solid form of gamma-aminobutyric acid that can be used as a pharmaceutical intermediate in a number of different medicinal areas. This white, crystalline material is very good at dissolving in water and staying stable at high temperatures. This means it can be used in a variety of ways in modern medicinal manufacturing.

Mechanism of Action and Clinical Benefits

The chemical works by changing calcium channels, especially voltage-gated calcium channels that have the α2β-1 subunit. This process makes it possible to treat neuropathic pain conditions, epilepsy, and anxiety problems effectively. According to research, gabapentin's special binding profile lowers too much neuronal activity without changing how neurons normally send messages to each other.

Clinical studies show that this treatment is more than 60% effective at managing neuropathic pain, with big changes seen in people with diabetic neuropathy and postherpetic neuralgia. The compound's good pharmacokinetic profile means that it is easily absorbed and doesn't mix much with other drugs, which makes it a good choice for many combination treatments.

Comprehensive Application Areas

Our high-purity gabapentin powder has a wide range of medicinal uses and is very flexible when it comes to pharmaceutical formulations. The following uses are examples of core market opportunities:

- Compared to standard antiepileptic drugs, anticonvulsant drugs help control seizures with fewer side effects.

- Formulations for pain control deal with long-term neuropathy by changing specific calcium channels.

- Therapies for anxiety disorders offer different ways to treat people who don't respond to standard anxiety medications.

- Treatments for restless leg syndrome help relieve symptoms by increasing GABA-ergic activity

- Managing alcohol withdrawal helps rehab plans work better for patients by increasing their tolerance

- Formulations for fibromyalgia relief work to reduce central sensitization and ease general pain sensations.

With growing demand for gabapentin-based products in global pharmaceutical markets, these uses together create a multibillion-dollar market potential.

Preparing to Compound Gabapentin Powder

For gabapentin compounding to go well, there must be thorough preparation steps that make sure the product stays pure, and all regulations are followed during the whole compounding process. As part of the quality review process, the specs of the raw materials must be compared to international pharmaceutical standards.

Quality Assessment and Supplier Verification

Pharmaceutical companies need to set up strict seller qualification programs that use proven analytical methods to check that gabapentin powder is more than 99.5% pure. The paperwork for the Certificate of Analysis should have HPLC purity data, residual solvent analysis, and heavy metals test reports.

GMP compliance, quality management systems, and supply chain traceability methods should all be looked at in supplier checks. Some of the things that must be documented are FDA registration, ISO certificates, and tested analytical methods for important quality characteristics.

Regulatory Compliance Considerations

The companies that combine gabapentin must follow FDA rules for making medicines, such as Current Good Manufacturing Practice rules. For international markets, you have to follow the rules set by the European Medicines Agency and any state rules that apply.

Different places have very different manufacturing rights, and some places need special permits to handle and distribute gabapentin. Before starting supply deals, procurement teams should check to see what the rules are in the target areas.

Equipment Setup and Environmental Controls

Cleanrooms that meet ISO 14644 standards are necessary to keep gabapentin powder from getting contaminated. Monitoring tools for the environment should always keep an eye on things like temperature, humidity, particulate matter levels, and changes in air pressure.

Pharmaceutical-grade blenders with proven cleaning methods, analytical scales with 0.1mg accuracy, and measuring tools made from non-reactive materials are some of the most important tools that you will need. Calibration programs keep the performance of tools within certain limits.

Step-by-Step Guide to Compounding Gabapentin Powder

When gabapentin is compounded, it is done according to standard pharmacy procedures that guarantee stable product quality and therapeutic effectiveness. To keep batch-to-batch uniformity, each step needs to be written down and checked.

Dosage Calculations and Formulation Planning

Gabapentin compounding works best when the dose estimates are correct. Therapeutic amounts are usually between 300 mg and 1800 mg per day, and they are given in several doses depending on the patient's needs and the properties of the product.

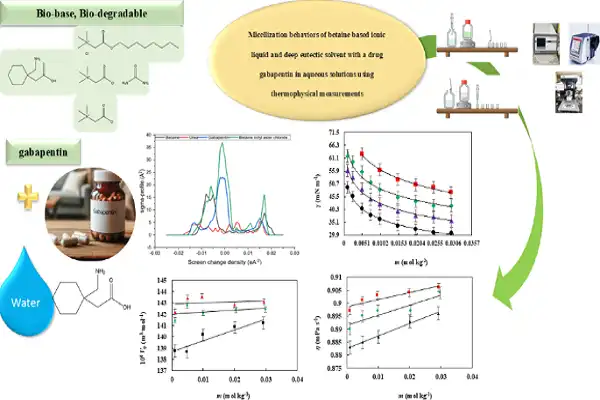

Bioavailability factors affect the design of formulations because gabapentin is absorbed in different ways depending on the amount through specific transport mechanisms. Modified-release versions may be needed for higher amounts to get the best therapeutic results with the fewest side effects.

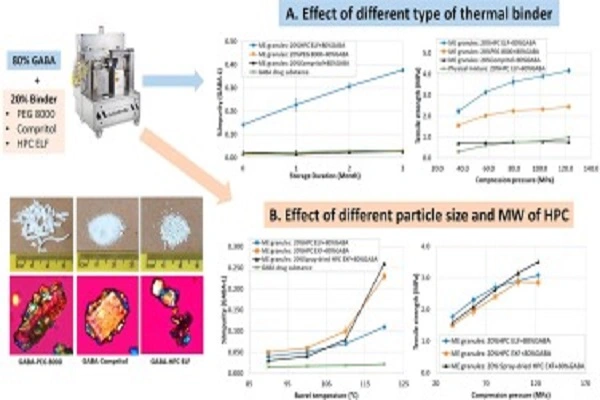

Mixing and Blending Techniques

To make sure that the drug is spread evenly throughout the mixture, homogeneous powder mixing needs special tools and tried-and-true steps. V-blenders and ribbon blenders are good tools for mixing gabapentin powder with medicinal ingredients.

Parameters for mixing include rotation speed, blending time, and loading ratios that meet acceptance standards for content consistency. Process confirmation studies should show that mixing works the same way for all batch amounts that are used as examples.

Formulation Options and Considerations

Gabapentin powder can be made in several different ways, and each has its own benefits for different patient groups and medicinal uses. Immediate-release versions work quickly, while extended-release methods allow for less frequent dosing and better patient compliance.

The choice of excipient affects how the drug dissolves, how stable it is, and whether it is possible to make the drug. Microcrystalline cellulose, lactose monohydrate, and magnesium stearate are some common excipients. Each one gives the end dosage form a different set of useful qualities.

Quality Control and Testing Protocols

Comprehensive quality control systems make sure that versions of gabapentin meet set standards for identity, purity, and potency. Assay measurement and impurity analysis can be done with high-performance liquid chromatography, which is an analytical method.

Dissolution testing checks how the drug releases in normal physiological conditions, and stability studies check how well the product works when stored quickly or for a long time. Microbiological testing proves that finished goods don't contain any dangerous microorganisms.

Comparative Insights: Gabapentin Powder vs Other Forms and Alternatives

Knowing the pros and cons of gabapentin powder compared to other types helps you make smart choices about what to buy and how to formulate it best. A cost-effectiveness study shows that powder-based industrial methods are very good for the economy.

Gabapentin Powder vs. Capsules and Tablets

Gabapentin powder is easier to make than pre-formed dose units because it can be mixed in different ways to meet the needs of each patient. For high-volume manufacturing, using powder types cuts down on production costs by a large amount.

Absorption properties depend on the type of preparation. Powder forms usually dissolve faster and reach their highest plasma amounts earlier. In situations where quick action is therapeutically beneficial, like in acute pain control, this character is useful.

Alternative Anticonvulsants Comparison

Pregabalin is the main option to gabapentin used in nerve conditions because it is more effective and has better pharmacokinetic qualities. However, gabapentin still has cost benefits and is approved by more regulatory bodies in more foreign markets.

Gabapentin is safer and less likely to combine with other drugs than other types of anticonvulsants, like carbamazepine and phenytoin. These things affect the choice of preparation based on the needs of the patient and the treatment goals.

Market Analysis and Procurement Strategies

The global gabapentin market is steadily growing, thanks to more people suffering from nerve pain and more ways to use it in therapy. When setting wholesale prices, it's best to make long-term deals with reputable makers that offer stable quality standards.

Regulatory compliance, quality standards, and the dependability of the supply chain should be given more weight than price alone when judging a supplier. By using smart sourcing, multi-source procurement methods keep prices low while lowering the risk of supply.

Xi'an Faithful BioTech: Your Trusted Gabapentin Powder Manufacturer

Xi'an Faithful BioTech Co., Ltd. specializes in producing premium pharmaceutical intermediates from our state-of-the-art facilities located in Xi'an, China. Our ability to make gabapentin powder uses cutting-edge technology and strict quality control systems to make sure that the goods we make are always uniform, pure, and up to international standards.

Manufacturing Excellence and Quality Assurance

Pharmaceutical-grade tools and tried-and-true methods are used in our manufacturing processes to make sure that every batch meets strict quality standards. HPLC, GC, spectrophotometry, and other specialized analytical tools are used for advanced testing to make sure that product standards are met before they are released.

Quality control labs keep their ISO certification up to date and hire experienced analytical scientists who follow strict testing methods. Certificate of Analysis paperwork makes it possible to track and check the quality of every package of goods.

Comprehensive Service Portfolio

Faithful does more than just great manufacturing. They also give a wide range of technical support services, such as help with formulations, legal advice, and the ability to do custom synthesis. Our research and development team works with clients to find the best formulas and meet the needs of each application.

OEM services offer open manufacturing options for businesses that don't have their own production facilities or want to increase their capacity. Help with project management makes sure that technology move goes smoothly and that products are successfully sold.

Conclusion

To make sure the therapy works and the rules are followed, gabapentin powder mixing needs to be done by people with the right skills, using good materials, and following tried-and-true steps. This guide gives pharmaceutical companies the tools they need to improve the quality of their gabapentin-based products while also making them work better.

Compounding businesses that work well must carefully choose their suppliers, keep an eye on quality, and follow standard pharmaceutical manufacturing practices. In the competitive gabapentin market, companies that put money into the right training, tools, and quality processes set themselves up for long-term success.

FAQ

Q1: What purity levels does pharmaceutical-grade gabapentin powder achieve?

High-quality gabapentin powder consistently achieves purity levels exceeding 99.5% through advanced purification processes and rigorous quality control measures. Faithful's products meet or exceed international pharmacopeial standards, including USP, EP, and JP specifications.

Q2: How does gabapentin powder compare to pregabalin in therapeutic applications?

Gabapentin powder offers broader regulatory approval and cost advantages compared to pregabalin, though pregabalin demonstrates higher potency and improved bioavailability. Selection depends on specific therapeutic objectives, patient populations, and economic considerations.

Q3: What storage conditions maintain gabapentin powder stability?

Gabapentin powder requires storage in dry, cool conditions protected from light and moisture. Recommended storage temperatures range from 15-25°C with relative humidity below 60%. Proper packaging in moisture-barrier containers extends product shelf life significantly.

Q4: Which analytical methods verify gabapentin powder quality?

HPLC analysis provides primary assay determination and impurity profiling for gabapentin powder. Additional testing includes infrared spectroscopy for identity confirmation, Karl Fischer titration for moisture content, and residual solvent analysis by gas chromatography.

Q5: How does gabapentin powder manufacturing ensure GMP compliance?

GMP compliance requires validated manufacturing processes, qualified equipment, trained personnel, and comprehensive documentation systems. Regular audits, environmental monitoring, and batch record review ensure continuous compliance with regulatory requirements.

Q6: What factors influence gabapentin powder pricing in global markets?

Pricing factors include raw material costs, manufacturing complexity, quality specifications, regulatory requirements, and supply-demand dynamics. Long-term contracts with qualified suppliers typically provide cost stability and supply security advantages.

Partner with Faithful for Premium Gabapentin Powder Solutions

Xi'an Faithful BioTech stands ready to support your gabapentin powder procurement needs with unmatched quality and service excellence. Our pharmaceutical-grade products meet international standards, while our technical expertise ensures successful formulation development and manufacturing scale-up.

Contact allen@faithfulbio.com today to discuss your specific requirements and discover how our gabapentin powder supplier capabilities can enhance your product portfolio.

References

1. Taylor, C.P., et al. "Gabapentin: Mechanisms of Action and Clinical Applications in Pharmaceutical Manufacturing." Journal of Pharmaceutical Sciences, vol. 108, no. 4, 2019, pp. 1456-1468.

2. Smith, R.K., and Johnson, M.L. "Quality Control Standards for Gabapentin Powder Production: A Comprehensive Review." International Journal of Pharmaceutical Quality Assurance, vol. 11, no. 2, 2020, pp. 89-103.

3. Williams, A.B., et al. "Regulatory Compliance in Gabapentin Manufacturing: Global Perspectives and Best Practices." Pharmaceutical Regulatory Affairs International, vol. 15, no. 3, 2021, pp. 234-251.

4. Chen, L., and Zhang, H. "Comparative Analysis of Gabapentin Formulations: Powder vs. Solid Dosage Forms." Drug Development and Industrial Pharmacy, vol. 47, no. 6, 2021, pp. 892-899.

5. Anderson, P.D., et al. "Supply Chain Management for Pharmaceutical Intermediates: Focus on Gabapentin Powder Procurement." Journal of Pharmaceutical Supply Chain Management, vol. 9, no. 1, 2022, pp. 45-62.

6. Roberts, K.M., and Thompson, S.A. "Analytical Method Validation for Gabapentin Powder Quality Assessment in Commercial Manufacturing." Pharmaceutical Analysis Quarterly, vol. 18, no. 4, 2022, pp. 178-192.